PEB System

Primary Built-up Members mainly consists of

- Built-up "|" shaped primary structural framing members

- Columns

- Rafters

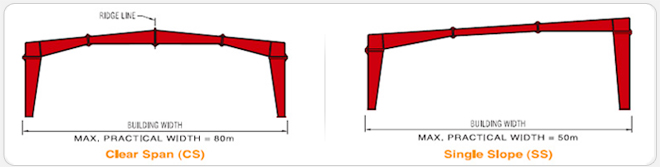

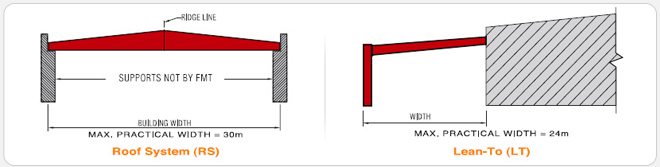

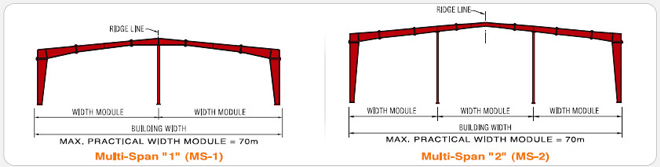

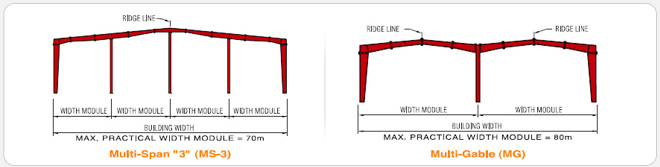

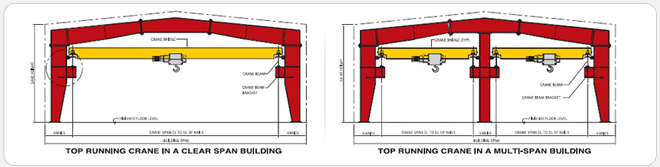

These members are fabricated from high strength grade plates, which are cut to size and shape as per the specifications, which are used in making Built-up sections. In this system practically any geometrical frame is possible. Unsymmetrical framing systems about the ridge line and multiple framing systems with unequal width are also possible, but they require more engineering time and longer delivery periods. All the above components are designed in such a manner that they are compatible with each other. The fabrication of these components is carried out under strict quality control norms as per detailed shop drawings. Functional subsystems include mezzanine floors (including joists and decking), crane runaway beams (to support crane systems), roof platforms, catwalks, etc. Aesthetic features include fascias, parapets, canopies and roof extensions. These components are transported to site with proper markings and are assembled at site as per erection drawings.

Secondary Built-up Members mainly include

- Purlins

- Eave Struts

- Side Runners

- Fascia Channels

- Door Posts

- Window Posts

- Rafters Stays

- Column Stays

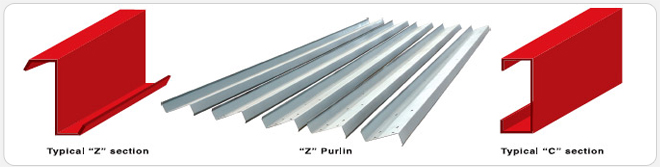

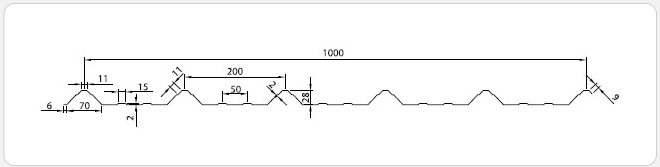

- Base Angles Cold-formed "Z" and "C" shaped secondary structural members are Cold Roll Formed light gauge, which are made as per the design requirement and consists of;

- Roof Purlin

- Eave Struts

- Well Girts

The sheets and panels provided by us are of Galvanized/Galume Aluminum/Stainless Steel, Cold Rolled Low Carbon Steel Coils. They are of Two Coat Two Back Colour Coating Line of RMP/SDP/PU/SMP/PVDF/Plastisol Paint, solvent & Water Base PU & Polyester Guard Film.

These basically consist of- Metal Roofing/Wall Cladding

- Connection Fasteners

- Sky Light(Sky Light & Poly Carbonate)

- Turbo Ventilator

- Ridge Ventilator

- Roof Curbs

- Gutter

- Window

- Door

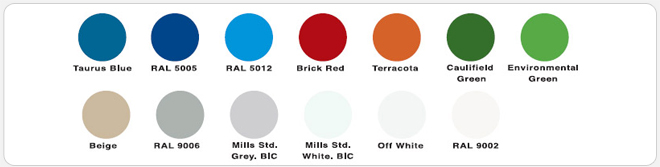

Available Color Shades